Your home’s electrical panel, often hidden away in a basement, garage, or utility closet, is the central nervous system of its power supply. It distributes electricity safely throughout your house, powering everything from your lights and appliances to your heating and cooling systems. However, like any crucial component, it’s susceptible to wear and tear, and one of the most insidious threats it faces is corrosion. Recognizing breaker panel corrosion signs early can be the difference between a minor repair and a catastrophic electrical fire or system failure. This comprehensive guide will equip you with the knowledge to identify these critical warning signs, understand the risks, and know when to call a professional to ensure your home remains safe and powered.

The Critical Role of Your Electrical Panel

Often referred to as a service panel, load center, or breaker box, the electrical panel is the gateway for electricity entering your home. It houses circuit breakers, which are safety devices designed to trip or “break” a circuit when they detect an overload or a short circuit. This action prevents wiring from overheating, potentially averting fires and protecting your appliances. Without a properly functioning electrical panel, your home’s entire electrical system is at risk, and corrosion poses a direct threat to its integrity and safety mechanisms.

Understanding Corrosion: What It Is and Why It Happens in Electrical Panels

Corrosion is a natural process that degrades materials, typically metals, through chemical or electrochemical reactions with their environment. In the context of an electrical panel, this usually means the oxidation of metal components like bus bars, terminals, screws, and wiring. Several factors can contribute to corrosion within this sensitive environment:

- Moisture: This is the primary culprit. High humidity, water leaks from pipes, condensation, or direct water exposure (e.g., from a leaky roof or basement flood) can significantly accelerate corrosion. Even small amounts of moisture over time can be detrimental.

- Chemical Exposure: Storing corrosive chemicals like cleaning agents, fertilizers, or pool chemicals near the electrical panel can release vapors that react with the metal components, leading to corrosion.

- Galvanic Corrosion: This occurs when two different metals are in electrical contact in the presence of an electrolyte (like moisture). The more active metal corrodes preferentially. In an electrical panel, this can happen between copper wiring and aluminum terminals, or various metal alloys used in breakers and bus bars.

- Age and Wear: Over time, even without obvious moisture, components can slowly degrade. The protective coatings on metals can break down, exposing them to ambient air and humidity.

- Poor Installation or Maintenance: Loose connections can generate heat, leading to faster degradation of materials. Incorrectly sized components or shoddy workmanship can also create conditions ripe for corrosion.

Unmasking the Danger: Key Breaker Panel Corrosion Signs to Look For

Inspecting your electrical panel is not a DIY task for the inexperienced, especially when it comes to opening the main cover. However, many visible signs of corrosion can be spotted on the exterior or through the gaps around the breakers without directly touching live components. If you notice any of these signs, it’s imperative to contact a qualified electrician immediately. Never attempt to open or work on your electrical panel yourself.

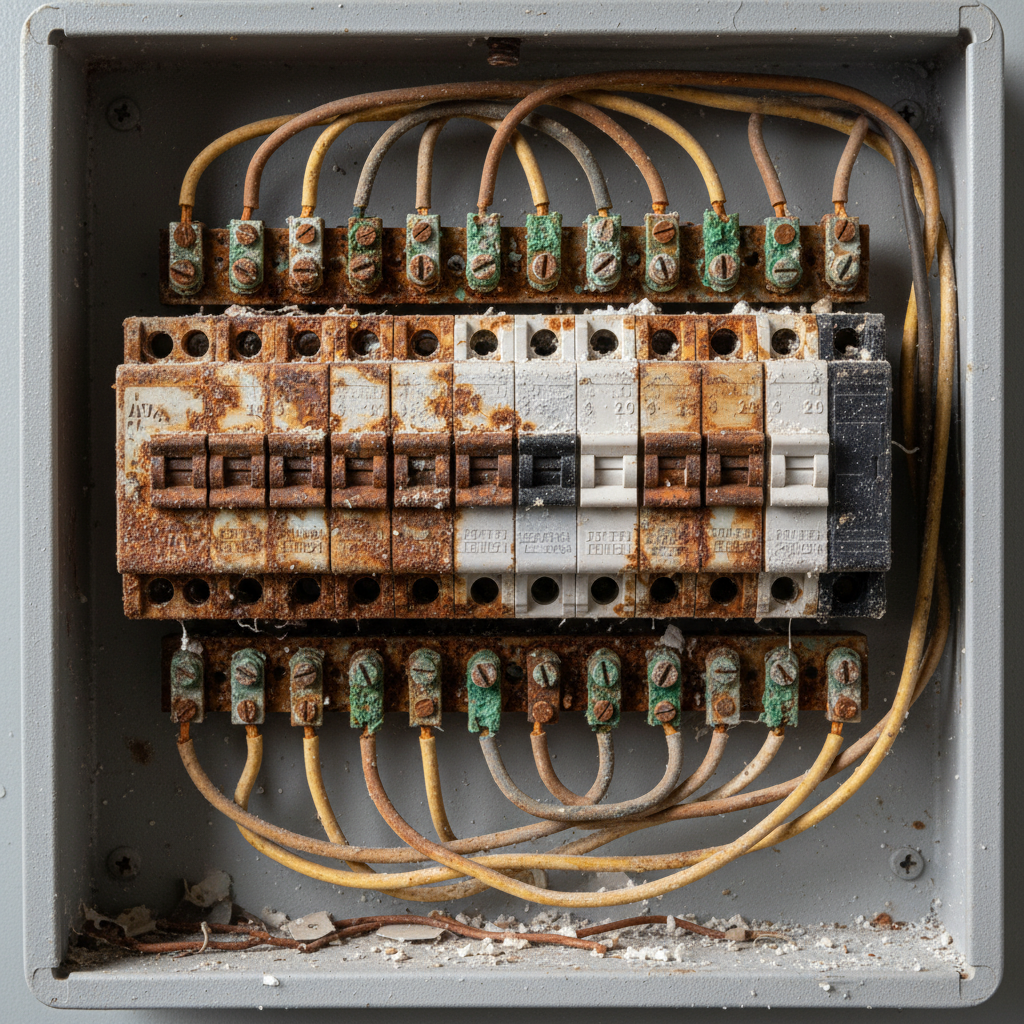

Visible Rust and Discoloration

This is perhaps the most obvious and common indicator of corrosion. Look for:

- Orange or Brown Rust: On the metal casing of the panel itself, on the circuit breaker handles, or around the screws and connections. This is a clear sign of iron or steel oxidizing due to moisture.

- Green or Blue Residue: Often found on copper wiring or terminals, this indicates copper corrosion (verdigris).

- White Powdery Substance: A fluffy, white, or chalky deposit can signify aluminum corrosion, which is particularly concerning as aluminum corrosion products are non-conductive and can lead to resistance and heat buildup.

- Darkened or Burnt Areas: Any black or scorched marks on breakers, wiring, or the panel interior (if visible through gaps) suggest overheating, which can be caused or exacerbated by corrosion-induced resistance.

These visible cues are red flags that moisture has infiltrated the panel and is actively damaging its components, potentially compromising electrical conductivity and safety.

Pitting or Flaking Metal

Corrosion doesn’t just disfigure surfaces; it can eat away at the metal itself. If you observe any of the following, corrosion is advanced:

- Pitting: Small depressions or holes on metal surfaces where material has been lost due to corrosion.

- Flaking or Crumbling Metal: Components that appear to be disintegrating or shedding layers of metal. This is a severe sign that the structural integrity of the electrical parts is compromised.

- Distorted Components: Metal parts that look bent, warped, or otherwise not in their original shape, possibly due to expansion from corrosion products or heat.

Such physical degradation means the components may no longer be able to perform their function safely or reliably, increasing the risk of failure.

Strange Odors

Your nose can be a powerful detector of electrical problems. Electrical issues, especially those involving corrosion and overheating, often produce distinct smells:

- Burning Smell: A strong, acrid odor like burning plastic or rubber is a critical warning sign of overheating wires or insulation. Corrosion can cause increased resistance, leading to excessive heat.

- Metallic or Fishy Smell: Sometimes described as a “fishy” or “ozone-like” smell, this can indicate arcing, sparking, or melting plastic insulation due to overheating.

- Musty or Damp Smell: While not directly an electrical smell, a persistent musty odor around the panel suggests a moisture problem, which will inevitably lead to corrosion if not addressed.

Never ignore unusual smells coming from your electrical panel; they are often precursors to serious hazards.

Audible Clicks, Buzzing, or Crackling

A healthy electrical panel should operate silently. Any audible sounds are a cause for concern:

- Frequent Clicking: While a breaker clicking when it trips is normal, constant or random clicking sounds within the panel are not. This could indicate a faulty breaker or loose connections.

- Buzzing or Humming: A persistent buzzing sound often points to loose connections or excessive vibration, which can be exacerbated by corroded terminals that don’t make firm contact.

- Crackling or Sizzling: These sounds are highly dangerous, suggesting arcing or sparking inside the panel. Arcing occurs when electricity jumps across a gap, generating intense heat and posing an immediate fire risk. Corrosion can create the gaps or resistance needed for arcing to occur.

These sounds are not just annoying; they are a direct indication that something is fundamentally wrong with the electrical flow and connections within your panel.

Frequent Breaker Trips

Circuit breakers are designed to trip when there’s an electrical overload or a short circuit to prevent damage and fire. However, if a specific breaker, or multiple breakers, trip frequently without any obvious overload (e.g., you haven’t plugged in new appliances or are running too many devices on one circuit), it could be a sign of a problem within the panel itself, including:

- Corroded Connections: Corrosion increases resistance, which can be interpreted as an overload by the breaker, causing it to trip prematurely.

- Faulty Breaker: Corrosion can damage the internal mechanisms of the breaker, making it overly sensitive or unable to hold a load.

- Ground Faults or Short Circuits: While corrosion might not be the direct cause, it can expose wires or create pathways that lead to these dangerous conditions.

Consistent, unexplained tripping warrants immediate investigation by a professional.

Flickering Lights or Power Fluctuations

Inconsistent power delivery throughout your home can often be traced back to the electrical panel. If you notice lights flickering randomly, appliances not receiving consistent power, or devices momentarily losing power, it might indicate:

- Loose Connections: Corrosion can loosen connections over time by degrading the metal or interfering with the conductivity.

- Degraded Bus Bars: The main power distributors within the panel, bus bars, if corroded, can’t evenly distribute power.

- Compromised Main Breaker: The main breaker, affected by corrosion, might not be providing stable power to the entire panel.

These fluctuations not only are annoying but can also damage sensitive electronics and appliances.

Heat or Warmth Around the Panel

Your electrical panel should generally be cool to the touch. If you feel warmth or heat radiating from the panel cover, especially in specific areas, it’s a critical warning sign of overheating inside. Overheating is a common consequence of corrosion because:

- Increased Resistance: Corroded connections have higher electrical resistance. When current flows through high resistance, it generates heat (Joule heating).

- Loose Connections: Loose connections, often a result of corrosion or improper installation, also generate significant heat due to arcing or poor contact.

Persistent heat is a serious fire hazard and should prompt an immediate call to an electrician. For more information on preventing electrical hazards in your home, consult Good Housekeeping’s electrical safety tips.

Loose or Damaged Wiring

While this might require a trained eye to spot through the gaps, visible signs of wire damage around the panel can also indicate deeper issues. Look for:

- Frayed or Exposed Wires: If insulation is damaged, exposing the copper conductor.

- Discolored Wiring: Wires that appear burnt, melted, or discolored, particularly near the terminals.

- Wires Pulling Away: Wires that seem loose or are visibly pulling away from their terminal connections.

Corrosion can weaken wire connections, making them more susceptible to pulling out or causing the insulation to degrade, leading to exposed live wires and potential short circuits.

Water Marks or Moisture Accumulation

This is a direct visual cue that moisture is or has been present. Look for:

- Water Stains: On the panel cover, the wall around the panel, or on the floor beneath it.

- Condensation: Visible droplets of water or a persistently damp feel on the exterior of the panel, especially in humid environments.

- Puddles: Any standing water on the floor near the panel, indicating a significant leak.

Where there is moisture, corrosion will follow. Identifying and addressing the source of the water is as important as rectifying the corrosion itself.

The Serious Risks of Neglecting Corrosion

Ignoring breaker panel corrosion signs is akin to playing with fire—literally. The consequences can be severe and life-threatening:

- Fire Hazard: This is the most significant risk. Corrosion causes increased resistance and overheating, which can ignite insulation, wiring, and surrounding combustible materials.

- Electrical Shock and Electrocution: Compromised insulation, exposed live parts, or damaged components due to corrosion can lead to accidental contact with live electricity, resulting in severe shocks or fatalities.

- Damage to Appliances and Electronics: Unstable power delivery, voltage fluctuations, or short circuits caused by corrosion can fry sensitive electronics and render expensive appliances unusable.

- Power Outages: A corroded panel is a unreliable panel. It can lead to partial or complete power outages in your home, causing inconvenience and potential financial loss (e.g., spoiled food).

- Costly Repairs: The longer corrosion is ignored, the more extensive the damage becomes, leading to more complex and expensive repairs, potentially even requiring a full panel replacement.

Preventive Measures: Keeping Your Electrical Panel Corrosion-Free

While you should never attempt to service your electrical panel yourself, there are steps you can take to minimize the risk of corrosion and ensure its longevity:

- Regular Professional Inspections: Schedule periodic inspections by a qualified electrician, especially if your home is older or if the panel is located in a damp environment like a basement or garage. An electrician can safely open the panel, inspect internal components, and identify early signs of corrosion or potential issues.

- Control Moisture: Ensure your basement or garage is dry. Use dehumidifiers if humidity is high. Promptly repair any roof leaks, pipe leaks, or foundation issues that could introduce water near the panel. Ensure proper ventilation in areas prone to dampness.

- Maintain Clear Space: Keep the area around your electrical panel clear of clutter. This improves air circulation and makes it easier to spot issues. Avoid storing combustible materials nearby.

- Avoid Chemical Storage: Never store corrosive chemicals, paints, solvents, or strong cleaning agents in the immediate vicinity of your electrical panel. Their fumes can accelerate corrosion.

- Proper Installation and Repairs: Always use a licensed and experienced electrician for any electrical work, especially panel installations, upgrades, or repairs. Professional work ensures correct wiring, tight connections, and appropriate sealing to prevent moisture intrusion.

- Monitor Environmental Factors: If your panel is in an outdoor location, ensure its enclosure is sealed and rated for outdoor use, regularly checking for cracks or damage to the weatherproof casing.

When to Call a Professional Electrician

Let’s be unequivocally clear: any suspicion of electrical panel corrosion or malfunction warrants an immediate call to a licensed electrician. Electrical work is not a DIY project. The risks of electric shock, fire, and serious injury are too high. You should contact a professional if you notice:

- Any of the corrosion signs mentioned above (rust, discoloration, strange smells, sounds, flickering lights, heat, etc.).

- Frequent or unexplained circuit breaker trips.

- Discolored or warm outlets, or sparks from outlets.

- A general feeling that “something isn’t right” with your home’s electricity.

- You are buying an older home and want a thorough electrical system inspection.

An electrician has the training, tools, and expertise to safely diagnose the problem, assess the extent of the corrosion, and recommend the necessary repairs or replacements, ensuring your home’s electrical system is safe and compliant with current codes.

FAQs About Breaker Panel Corrosion

Q1: Can I fix breaker panel corrosion myself?

Absolutely not. Attempting to fix corrosion in an electrical panel without professional training and safety equipment is extremely dangerous. You risk severe electrical shock, electrocution, or starting a fire. Always call a licensed electrician for any issues related to your electrical panel.

Q2: How often should I inspect my electrical panel for corrosion?

While a full internal inspection by a professional electrician is recommended every 3-5 years, or more frequently if your home is older or in a damp environment, you can visually check the exterior of your panel for obvious signs of damage, leaks, or rust annually. Remember not to touch anything and never open the panel cover.

Q3: Is corrosion always visible?

Not always. While severe corrosion often manifests with visible rust, discoloration, or odors, early stages of corrosion, or corrosion on internal components, might not be immediately apparent from the outside. This is why professional internal inspections are crucial for early detection.

Q4: What causes corrosion on the neutral bar?

Corrosion on the neutral bar (a common metal bus bar where all the neutral wires connect) is usually caused by the same factors as other parts of the panel: moisture, high humidity, or chemical exposure. Loose connections on the neutral bar can also generate heat, which can accelerate corrosion. A corroded neutral bar can lead to voltage imbalances and power fluctuations throughout your home.

Q5: Can humidity cause corrosion in an electrical panel?

Yes, high humidity is a major contributor to electrical panel corrosion. Constant exposure to moisture in the air can lead to condensation forming on metal components, accelerating the oxidation process. This is why it’s especially important to control humidity levels in basements, garages, and other areas where electrical panels are often located.

Conclusion

Your home’s electrical panel is a critical component that deserves attention and respect. Recognizing breaker panel corrosion signs is a vital skill for any homeowner concerned about safety and the longevity of their electrical system. From visible rust and strange odors to flickering lights and frequent breaker trips, these warning signs should never be ignored. By being vigilant and acting quickly to call a professional electrician at the first hint of trouble, you can protect your home, your appliances, and most importantly, your loved ones from the dangerous consequences of a compromised electrical panel. Prioritize electrical safety; it’s an investment in your peace of mind.