Understanding Your Heat Pump’s Anatomy

Before we pinpoint the source of that grating sound, it helps to understand the basic components of your heat pump system. A heat pump works by transferring heat, either from your home to the outside in cooling mode or from the outside into your home in heating mode. It consists of an outdoor unit (condenser/evaporator coil, compressor, fan) and an indoor unit (blower motor, coil). Both units have motors and moving parts that, under normal circumstances, operate with a low hum. When a grinding noise emerges, it often points to an issue with one of these mechanical elements.

- Compressor: The heart of the system, responsible for circulating refrigerant.

- Outdoor Fan Motor and Blades: Moves air over the outdoor coil.

- Indoor Blower Motor and Fan: Circulates conditioned air throughout your home.

- Bearings: Found in both the compressor and fan motors, allowing smooth rotation.

- Coils: Where heat exchange occurs.

Why is Your Heat Pump Making Grinding Noise? Common Culprits

A grinding noise is rarely good news, but identifying its origin is the first step toward a solution. Here are the most frequent reasons your heat pump might be producing this alarming sound:

Failing Motor Bearings

One of the most common causes of a grinding noise is worn-out or failing bearings in one of your heat pump’s motors. Both the outdoor fan motor, the indoor blower motor, and even the compressor itself contain bearings that allow their shafts to rotate smoothly. Over time, these bearings can lose lubrication, accumulate dirt, or simply wear out, leading to increased friction. This friction manifests as a distinct grinding, squealing, or rumbling sound.

- Outdoor Fan Motor Bearings: If the grinding is coming from your outdoor unit, especially when the fan is running, the bearings in the fan motor are a prime suspect.

- Indoor Blower Motor Bearings: If the noise originates from your indoor unit (furnace/air handler), particularly when air is being distributed, the blower motor bearings could be the culprit.

- Compressor Bearings: A grinding sound from the compressor is more serious and can indicate internal damage. This is often accompanied by a decrease in heating or cooling performance.

Ignoring failing bearings can lead to motor seizure and complete unit failure, requiring a more expensive replacement of the entire motor or compressor.

Loose or Damaged Fan Blades

Both the outdoor fan and the indoor blower fan have blades that move air. If any of these blades become loose, bent, or cracked, they can wobble and strike other components within the unit, creating a grinding or scraping noise. Debris entering the unit can also damage blades.

- Outdoor Unit Fan: A loose blade in the outdoor unit might hit the fan shroud or the coil, producing a rhythmic grinding sound as it rotates.

- Indoor Blower Fan (Squirrel Cage): The indoor blower is a squirrel cage-style fan. If it gets out of balance or accumulates dirt unevenly, it can vibrate excessively and grind against its housing.

A visual inspection (after safely shutting off power) can sometimes reveal visibly bent or broken fan blades.

Debris Inside the Unit

Nature and normal wear and tear can introduce foreign objects into your heat pump system. Leaves, twigs, dirt, small rocks, or even small animals (or evidence of them) can find their way into the outdoor unit. Inside, dust, pet hair, or pieces of insulation might accumulate. If these objects come into contact with moving parts like fan blades or motors, they can produce a grinding, rattling, or scraping sound.

Regular cleaning and ensuring the area around your outdoor unit is clear can help prevent this issue. It’s surprising what a small leaf or pebble can do when caught in a high-speed fan.

Worn Compressor Issues

The compressor is a complex, sealed unit, and internal problems can be very serious. A grinding noise directly from the compressor often indicates significant wear and tear, internal mechanical failure, or even a breakdown of its internal components. This could be due to failing internal bearings, a damaged crankshaft, or other critical issues. A failing compressor can be one of the most expensive repairs for a heat pump system, often leading to a discussion about replacing the entire outdoor unit or even the whole system.

Symptoms beyond grinding might include reduced heating/cooling, tripped circuit breakers, or the unit struggling to start.

Problems with the Blower Motor

As mentioned with bearings, the blower motor in your indoor unit is crucial for air circulation. Beyond just bearings, the motor itself can develop issues. A grinding noise might indicate a failing motor winding, a bent shaft, or other internal defects that cause parts to rub together. This can also lead to reduced airflow and inconsistent temperatures in your home.

Refrigerant Line Vibrations

While less common for a distinct “grinding” noise, sometimes refrigerant lines can vibrate excessively, especially if they are loose or rubbing against other components. This can create a sound that might be mistaken for grinding, though it’s often more of a buzzing or rattling. A technician can inspect the lines for proper insulation and secure mounting to prevent this.

Loose Components or Fasteners

Over years of operation, vibrations can cause screws, bolts, or other fasteners to loosen within both the indoor and outdoor units. When parts aren’t securely fastened, they can vibrate excessively and rub against other components, creating a grinding or rattling sound. This is often one of the simpler issues to diagnose and fix if caught early.

The Dangers of Ignoring a Grinding Heat Pump

That grinding noise isn’t just irritating; it’s a warning. Ignoring it can lead to a cascade of problems:

-

Escalating Repair Costs

A minor issue, like a failing bearing, can quickly escalate. If not addressed, the motor can seize, requiring a full motor replacement instead of just bearing lubrication or replacement. A small amount of debris can damage fan blades, leading to a more complex repair.

-

Reduced Efficiency and Higher Energy Bills

When components are grinding, they are working harder than they should, consuming more energy to perform the same task. This inefficiency translates directly into higher utility bills, eroding any savings you might have thought you gained by postponing repairs.

-

Complete System Failure

The worst-case scenario is a complete breakdown. A seized motor, a critically damaged compressor, or severe internal damage can render your heat pump inoperable, leaving you without heating or cooling until a major, potentially expensive, repair or replacement can be performed.

-

Safety Hazards

In some cases, internal damage can lead to electrical issues or overheating, posing a safety risk to your home. While rare, any unusual sounds from a major appliance should be treated with caution.

Troubleshooting Steps You Can Take (Safely!)

Before calling a professional, there are a few safe steps you can take to identify or potentially resolve the issue. Always prioritize your safety.

Safety First: Power Down the Unit

Before doing anything else, always turn off the power to your heat pump. This usually involves two steps: first, switching off the thermostat to the “off” position, and second, locating the dedicated circuit breaker for your heat pump in your electrical panel and flipping it to the “off” position. For the outdoor unit, there’s often a disconnect switch near the unit itself that you should also switch off. This prevents accidental startup and reduces the risk of electrical shock or injury from moving parts.

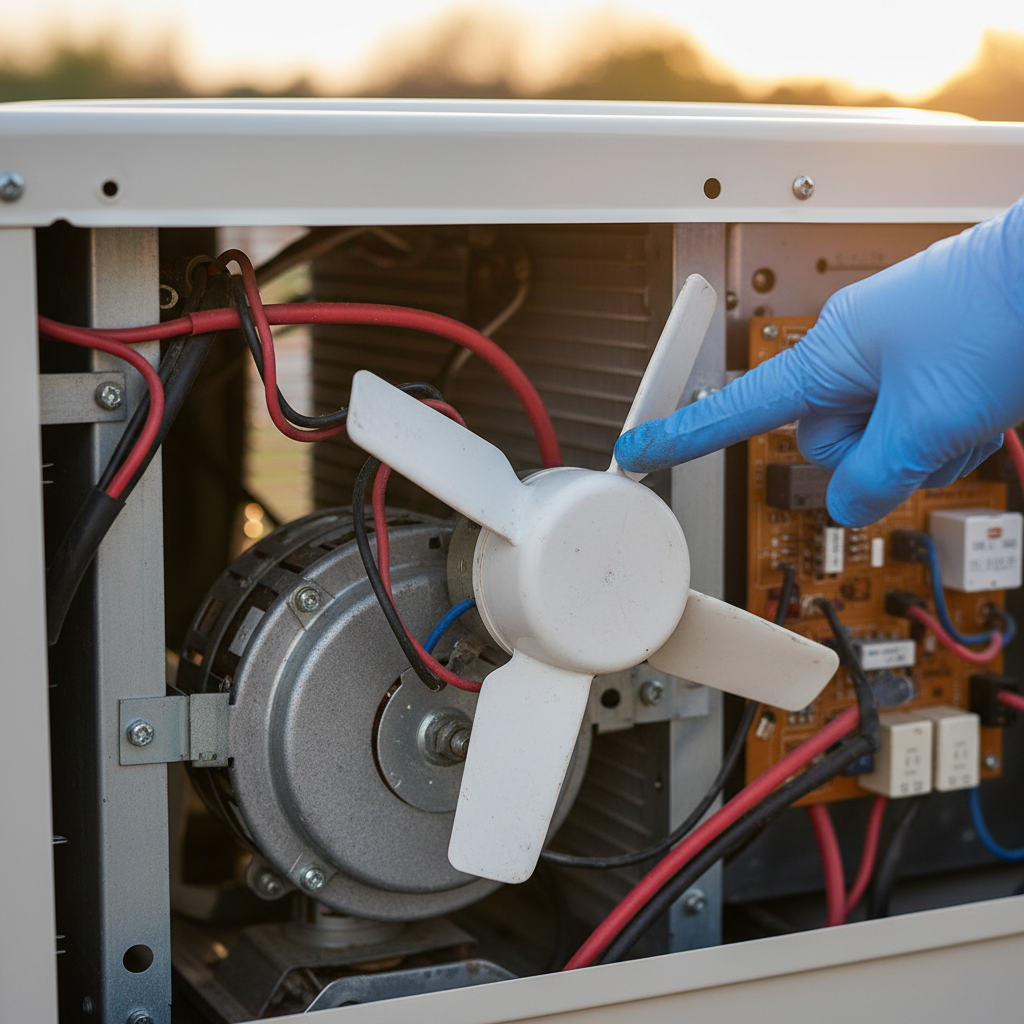

Visual Inspection of Outdoor Unit

Once power is off, you can safely inspect the outdoor unit.

- Check for Debris: Look inside the unit for leaves, twigs, dirt, or any other foreign objects that might be caught in the fan blades or resting on the coil. Carefully remove any debris.

- Examine Fan Blades: Inspect the fan blades for any visible damage – bends, cracks, or looseness. Try gently wiggling the blades to see if they are secure on the motor shaft. If they are loose or damaged, do not attempt to operate the unit.

- Look for Loose Components: Visually scan for any loose wires, covers, or other components that might be vibrating.

Visual Inspection of Indoor Unit

The indoor unit (often in a closet, basement, or attic) also needs attention.

- Check the Blower Compartment: If accessible, open the access panel to the blower compartment (again, only after confirming power is off). Look for debris, dirt buildup on the blower wheel (squirrel cage), or any signs of damage to the fan blades.

- Inspect Air Filters: While not directly related to grinding, a heavily clogged air filter can restrict airflow, causing the blower motor to work harder and potentially contribute to premature bearing wear. Replace if dirty.

Listen Carefully to Pinpoint the Source

If you’re unable to find a clear visual cause, and after carefully re-applying power (briefly, if safe to do so for testing), try to pinpoint exactly where the grinding noise is coming from. Is it louder near the outdoor unit’s fan? From the compressor? Or from the indoor air handler? This information will be invaluable when you speak to a technician.

When to Call a Professional HVAC Technician

While some minor issues like removing debris can be DIY fixes, many causes of a grinding heat pump require the expertise of a certified HVAC professional. Don’t hesitate to call one if:

-

Complex Internal Issues

Issues like failing motor bearings, a damaged compressor, or serious internal component damage require specialized tools, knowledge, and replacement parts. These are not DIY repairs.

-

Refrigerant Leaks

Though not directly causing grinding, refrigerant leaks can lead to compressor issues. Refrigerant handling requires certification and specialized equipment due to its environmental and safety implications.

-

Electrical Problems

Any electrical issue, especially in a high-voltage appliance like a heat pump, is best left to a professional to prevent injury or further damage.

-

Lack of Expertise or Tools

If you’re uncomfortable or unsure about any step, or if you lack the proper tools, it’s always safer and often more cost-effective in the long run to call a professional. They can accurately diagnose the problem and perform the repair correctly the first time.

A reputable HVAC technician can quickly diagnose the exact cause of the grinding noise, provide a clear explanation of the necessary repairs, and execute them safely and efficiently. Remember, early intervention can save you significant time, money, and stress.

Preventative Maintenance to Avoid Future Grinding Noises

Preventative care is key to extending the life of your heat pump and avoiding unexpected issues like grinding noises. Integrating regular maintenance into your home care routine can make a big difference:

-

Regular Filter Changes

Changing your air filters every 1-3 months (depending on usage, pets, and allergies) is one of the simplest yet most effective maintenance tasks. Clean filters ensure optimal airflow, reduce strain on the blower motor, and prevent dust buildup that could lead to problems.

-

Annual Professional Inspections

Schedule a professional HVAC tune-up at least once a year, ideally before the heating or cooling season begins. Technicians can spot potential problems like worn bearings, loose components, or minor debris accumulation before they escalate into major repairs. They’ll clean coils, check refrigerant levels, test electrical connections, and lubricate moving parts. For more comprehensive tips on maintaining your HVAC system, Good Housekeeping offers an excellent HVAC maintenance checklist.

-

Keeping the Area Around the Unit Clear

Ensure the outdoor unit has at least 2 feet of clear space on all sides. Remove any leaves, grass clippings, weeds, or other obstructions that could block airflow or get sucked into the fan blades. Trim back shrubs and plants. In winter, clear snow and ice from around the unit.

-

Checking for Loose Components

Periodically (during your annual cleaning or visual checks), you can gently check the outdoor unit’s casing and grilles to ensure all screws and fasteners are tight. Don’t overtighten, but ensure there’s no excessive wobble.

Conclusion

A heat pump making grinding noise is a clear signal that something is amiss within your system. While it can be a concerning sound, understanding the potential causes and knowing when to act can prevent a minor issue from becoming a costly catastrophe. From failing motor bearings and damaged fan blades to accumulated debris or serious compressor issues, each grinding sound tells a story of internal wear or external interference. Always prioritize safety by shutting off power before any inspection, and don’t hesitate to contact a qualified HVAC professional for diagnosis and repair. Regular preventative maintenance is your best defense, ensuring your heat pump runs smoothly, efficiently, and quietly for years to come, providing consistent comfort to your home.